The Ultimate Guide to Expanding Lifespan: Undercarriage Parts Maintenance Made Easy

The Ultimate Guide to Expanding Lifespan: Undercarriage Parts Maintenance Made Easy

Blog Article

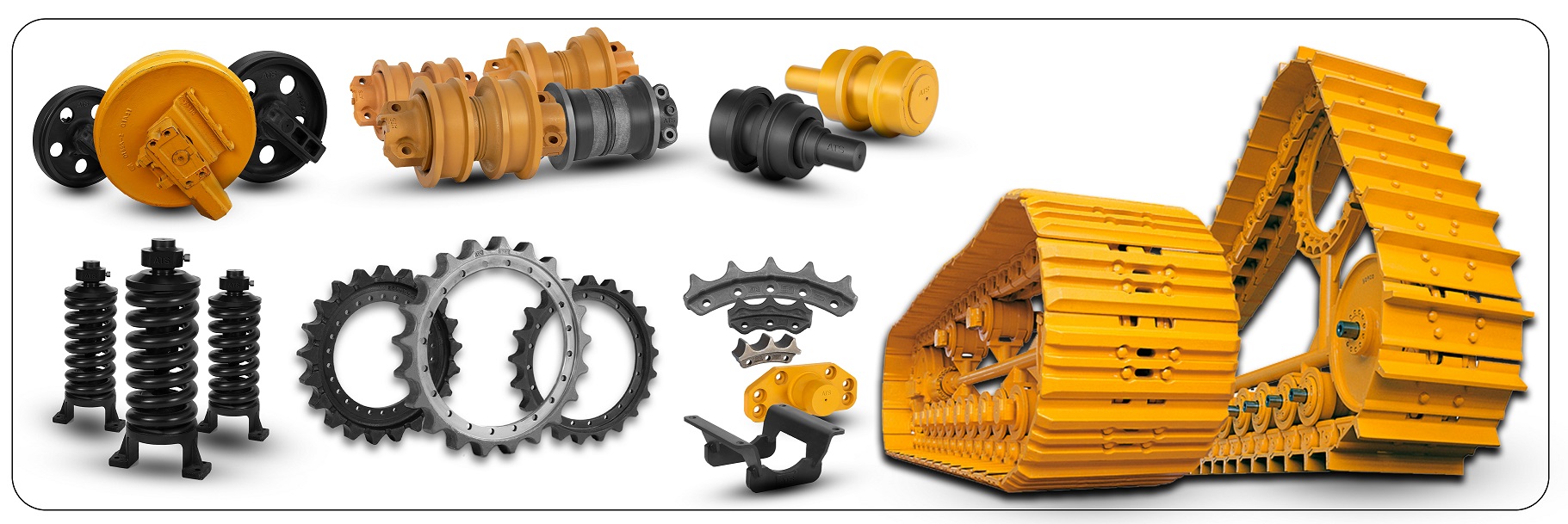

Discover Undercarriage Parts for Heavy Machinery

Recognizing the intricacies of undercarriage components is essential for the optimum efficiency and long life of hefty machinery. From track footwear to idlers, rollers, and gears, each component plays an essential duty in the performance of the tools. Exploring the specifics of these parts reveals a world of accuracy design and sturdiness that maintains hefty equipment operating at its optimal. Remain tuned as we reveal the importance of undercarriage components and explore the upkeep methods that can improve the efficiency of these important parts.

Importance of Undercarriage Parts

The undercarriage components of heavy machinery play a critical role in guaranteeing the total efficiency and longevity of the equipment. These parts, consisting of tracks, rollers, idlers, gears, and chains, form the foundation upon which the maker runs. A well-maintained undercarriage not just offers stability and support to the hefty equipment yet also contributes dramatically to its functional effectiveness and performance.

Among the crucial benefits of investing in high-quality undercarriage components is the reduction of downtime and maintenance costs. By making use of resilient components that can stand up to the rigors of heavy-duty applications, operators can reduce the requirement for frequent repair services and replacements, thus making best use of the maker's uptime and general life-span.

Additionally, appropriately operating undercarriage components ensure optimal weight distribution, grip, and ability to move, allowing the heavy equipment to operate efficiently even in difficult surfaces. This reliability is crucial for markets such as mining, building and construction, and farming, where equipment efficiency directly affects task timelines and success. To conclude, the importance of undercarriage components can not be overemphasized in preserving the efficiency and long life of heavy equipment.

Types of Track Shoes

When thinking about the various types of track shoes for hefty equipment, it is essential to review their design and capability in regard to particular operational demands. Track shoes are essential elements of the undercarriage system, offering grip, stability, and weight circulation for hefty machinery such as excavators, bulldozers, and spider cranes.

One of the most usual sorts of track footwear consist of:

** Grouser Shoes **: Including elevated metal bars (grousers) along the footwear's surface, these track shoes provide enhanced grip in challenging surfaces like mud, snow, and loosened crushed rock. undercarriage parts.

** Dual Grouser Shoes **: Similar to grouser shoes yet with an extra set of grousers, these track shoes supply also better grip and security, making them ideal for exceptionally rough surfaces.

** Triple Grouser Shoes **: With 3 collections of grousers, these track shoes provide maximum grip and stability, making them ideal for the most demanding problems.

Choosing the best kind of track shoe is important for enhancing the performance and durability of hefty machinery while making sure safety and security and effectiveness during operations.

Function of Rollers and Idlers

Rollers and idlers play integral duties in sustaining and directing the track footwear click for more info of hefty machinery during operation. Rollers are cylindrical elements that support the weight of the devices and ensure smooth motion along the terrain. They assist distribute the device's weight evenly, reducing endure the track footwear and minimizing vibrations. Idlers, on the other hand, guide the track chain and aid maintain correct tension. By avoiding excessive slack or tightness in the tracks, idlers add to the overall stability and performance of the machinery (undercarriage parts).

Additionally, idlers and rollers work together to maintain the track footwear abreast, stopping them from derailing or sliding off during procedure. Properly functioning rollers and idlers are important for ensuring the durability of the undercarriage system and optimizing the device's effectiveness. Normal upkeep and evaluation of these elements are essential to identify any signs of wear or damages beforehand, preventing expensive repair services and downtime in the future.

Role of Sprockets in Machinery

Upkeep Tips for Undercarriage Components

Effective upkeep of undercarriage parts is essential for making sure the long life and optimum efficiency of heavy machinery. Regular evaluation of undercarriage components such as track chains, rollers, idlers, gears, and track footwear is vital to avoid unforeseen malfunctions and expensive fixings. One essential maintenance suggestion is to keep the undercarriage clean from particles, mud, and various other pollutants that can speed up wear and look at this site deterioration. It is additionally essential to make sure proper track tension to prevent early endure components. Greasing the undercarriage components at suggested intervals helps to decrease friction and extend the lifespan of the parts. Keeping an eye on for any kind of uncommon noises, resonances, or modifications in device performance can suggest prospective problems with the undercarriage that call for immediate interest. By complying with these maintenance pointers vigilantly, heavy machinery operators can decrease downtime, minimize operating prices, and make the most of the efficiency of their devices.

Verdict

To conclude, the undercarriage components of heavy equipment play an essential duty in making sure the smooth performance and long go to this website life of the equipment. Recognizing the relevance of track footwear, idlers, gears, and rollers, as well as implementing correct maintenance practices, can considerably affect the general efficiency and effectiveness of the equipment (undercarriage parts). Regular assessment and prompt substitute of damaged components are necessary in taking full advantage of the lifespan and productivity of heavy equipment

Rollers and idlers play indispensable functions in supporting and leading the track shoes of heavy machinery during operation.In heavy machinery, sprockets offer a critical feature in transferring power from the engine to the tracks, enabling the tools to relocate efficiently and successfully. These components are connected to the axles or last drives of the equipment and work in conjunction with the tracks to push the equipment ahead or backwards. Regular evaluation of undercarriage components such as track chains, rollers, idlers, sprockets, and track footwear is important to protect against expensive repair work and unforeseen breakdowns. Comprehending the value of track shoes, idlers, sprockets, and rollers, as well as applying proper maintenance methods, can significantly influence the general performance and performance of the machinery.

Report this page